Elevator Installation for New Commercial Developments: A Complete Guide to Modern Building Solutions

You don’t just drop an elevator into a new commercial building and call it a day. The way it’s planned and put in will end up affecting how people actually use the place, every single day. Get that part wrong, and before long you’ll be hearing complaints, losing time, and paying more than you’d like to fix it. Get it right, and it quietly does its job for decades.

The best approach starts before the walls go up, with clear conversations between designers, engineers, and installers. Different buildings need different solutions. A small shopping center might get by with a

hydraulic lift

that’s steady and reliable, while a tall office block usually calls for a faster traction system that can handle big crowds.

Planning early lets you put the shaft where it works best, avoid awkward retrofits, and make it feel like part of the building rather than an add-on.

Along the way, you’ll be weighing things like how many people will ride at once, the busiest times of day, how much power the system will draw, and what it’ll take to keep it running. It’s a lot to think about, but those decisions up front are what make the difference between an elevator that simply works and one that works well for years.

Call Us 210-277-7772

Key Considerations for Elevator Installation in New Commercial Developments

You don’t just stick an elevator into a new building and call it done. It’s got to be in the right place, make sense with how people will actually move around inside, and meet whatever building rules or codes are in play. And once it’s there, you want it to work without needing a repair guy every few weeks. Even the details people rarely think about—how far the doors are from the main entrance, whether there’s enough space for a few people to wait, or which way the cab opens—can end up making life easier or more annoying. Miss those in the planning stage and, well, you’re stuck with them for as long as the building is standing.

Integrating Elevators Into Building Design

An elevator shaft has to work with the building’s structural grid and overall layout; otherwise, it can throw off the flow or waste valuable space. It usually makes sense to place elevator banks close to main entrances or other busy spots so people can find them without hunting around. The position of the core affects more than just convenience — it influences how mechanical systems, electrical wiring, and even emergency exits are arranged. Lobbies should give passengers enough room to wait without blocking hallways, and it helps if there’s a clear line of sight to the doors. The machine room also needs some thought — ventilation, access for maintenance, and day-to-day operations all come into play.

Machine-room-less (MRL) setups can save space, though they need special structural planning. You’ll need solid support around the shaft—usually reinforced concrete or strong load-bearing walls—and it’s worth sorting out things like floor-to-floor height and pit depth early on. Leave those until later and you might find yourself running into clearance headaches you didn’t plan for.

Compliance With Building Codes and Accessibility Standards

Elevators have to follow a long list of safety and accessibility rules, from national codes like ASME A17.1 and the National Electric Code to the International Building Code and whatever local changes a city might add. ADA requirements bring in their own set of details — cab size, door width, handrail height, and the inclusion of Braille and audio signals so the system works for everyone. Fire safety can’t be overlooked either; that means things like emergency recall functions and smoke detection. And in places prone to earthquakes, the whole setup needs extra reinforcement so it can keep running safely even when the ground moves.

Compliance With Building Codes and Accessibility Standards

Choosing the right elevator type starts with a clear understanding of how the building will be used — the height and number of stops, daily and peak traffic flow, and efficiency targets all play a role. Hydraulic elevators are cost-effective for low-rise buildings of two to five floors, while traction systems handle taller buildings more quickly and efficiently. MRL designs are great for saving space when that’s a priority. Calculations for speed, capacity, and number of cars help keep passenger wait times reasonable, especially during busy hours. Energy needs will vary by system, but for taller structures, traction systems often deliver better performance with lower long-term operating costs.

Call Us 210-277-7772

Elevator System Selection and Professional Installation Process

Putting in an elevator might sound like just another construction step, but it isn’t. You’ve got to think about it early—before walls are finished—so the design, the mechanics, and the safety side all fit together. Miss something now, and it’ll come back to bite you later. The system you choose will change how people move through the place, and in a subtle way, how the building feels to use.

Passenger, Freight, and Service Elevator Options

Passenger elevators are built for comfort and appearance, usually handling between 2,000 and 4,000 pounds, with clean interior finishes and modern floor displays.

Freight elevators are the workhorses, able to move loads of up to 20,000 pounds, with reinforced walls, wide doors, and heavy-duty parts meant for industrial use. Service elevators sit somewhere in between, carrying 3,000 to 5,000 pounds and combining elements of both passenger and freight designs, often with protective panels and door setups that make them practical for staff and deliveries.

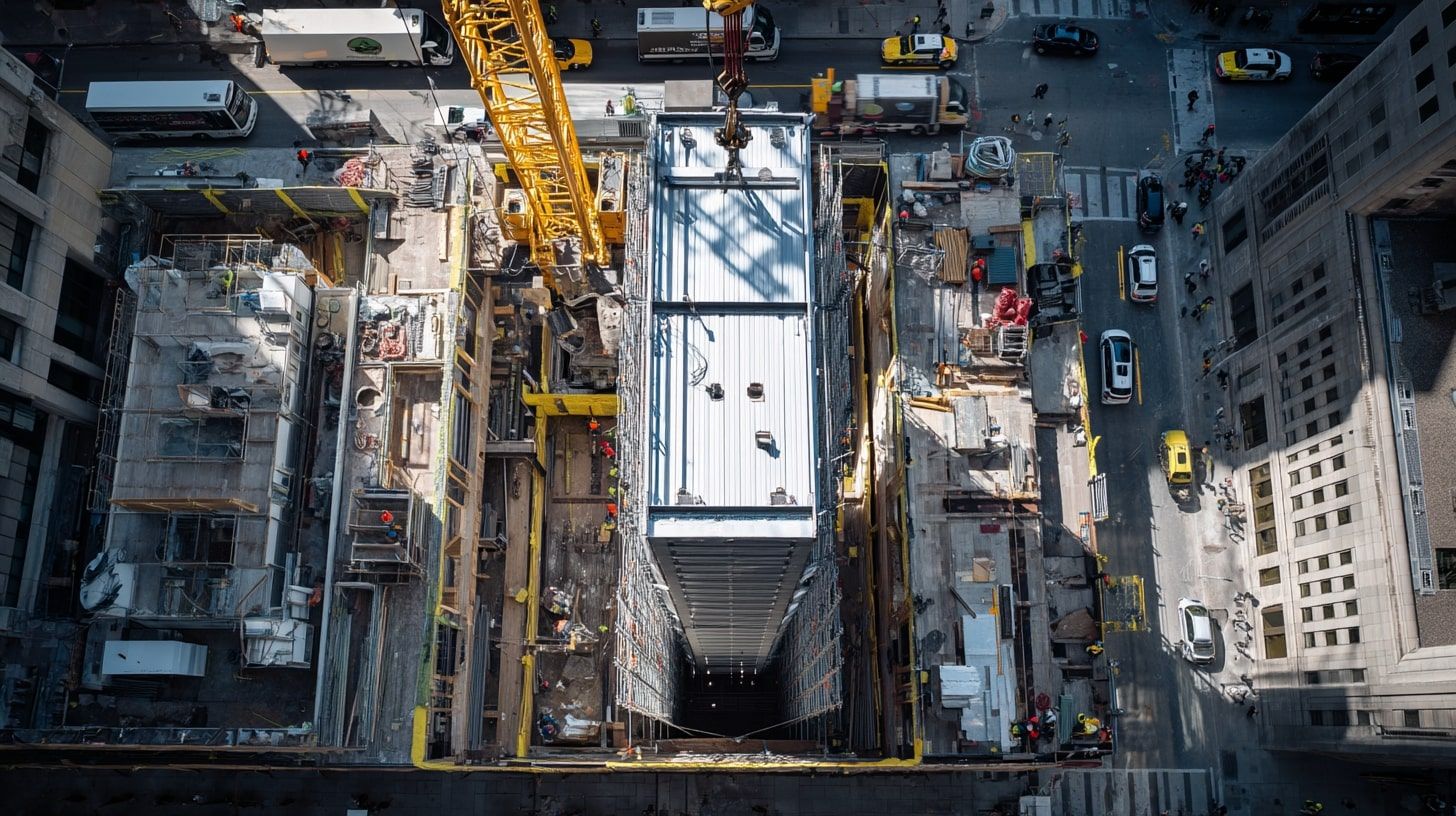

Steps of the Elevator Installation Process

We usually start by walking the site, checking the shaft size, and making sure the structure’s ready for what’s coming. Once that’s squared away, the guide rails go in and the hoistway gear gets bolted into place. The machine room gets its turn after that—controller, wiring, power hookups, all the guts that make the thing run. Then the cab’s put together, doors hung, and the inside finished off. The last part is more about tweaking than building: running the cables, balancing the counterweights, fine-tuning the doors, setting up the controls, and giving the backup systems a quick trial to be sure they’ll behave when it matters.

Essential Safety Features and Operational Testing

Elevators have more safety gear than most people realize. There are brakes that grab if the cables loosen, sensors so the doors won’t shut on someone, and weight limits that stop the lift from running if it’s overloaded. Before it’s signed off for use, the crew runs through a bunch of checks—emergency stops, the intercom, whether it lines up with the floor just right, that sort of thing. They’ll also load it down with extra weight to see if it handles what it’s meant to, and run it a few times to make sure it doesn’t slow down or act up depending on which floor it’s going to.

Frequently Asked Questions

Installing a commercial elevator isn’t just a matter of putting equipment in place—it takes planning, technical know-how, and an understanding of the rules that govern these systems. A good installation team handles all of that while making sure the end result adds value to the property and makes the building easier and more pleasant to use.

What are the advantages of integrating an elevator system during the initial construction phase of a new commercial development?

Putting in the elevator while the building is still going up can cut costs by as much as a third compared to adding it later. It also means you can place the shaft exactly where it works best, set up the machine room properly, and plan the electrical systems and structural supports from day one. This approach makes it easier to blend the elevator into the design so it feels like part of the building instead of an afterthought.

How do hydraulic elevators compare to traction elevators in terms of operation, cost, and suitability for commercial buildings?

Hydraulic elevators tend to cost less—around 15 to 20 percent cheaper to install—and they’re a good fit for buildings of five stories or less. They’re mechanically simpler, which means less upkeep. Traction elevators, on the other hand, move faster and handle tall buildings better, using counterweights that cut energy use by roughly 40 percent.

In what ways does undertaking professional commercial elevator installation impact the long-term value of a commercial property?

A professional job up front can save about a quarter of the maintenance costs over the system’s life, with fewer breakdowns and longer service. A modern, well-installed elevator also adds to property value by making the building more accessible and comfortable for tenants, and many newer systems use less energy, which is an added selling point.

What specific elevator design considerations must be taken into account for high-rise commercial buildings to ensure efficiency and safety?

In high-rises, the elevator setup needs careful traffic studies and sometimes zoning of certain cars to certain floors. They usually run between 500 and 1,000 feet per minute, and smart dispatch systems can cut wait times by about 40 percent during rush hours. Backup power is critical so cars can operate safely in an outage.

How can commercial elevator installation contribute to achieving LEED certification for environmentally sustainable buildings?

Choosing energy-efficient models can add up to six points toward LEED certification. Regenerative drives feed power back into the building’s electrical system on the way down, and features like LED lighting or automatic sleep modes can reduce power use by half during slow periods.

What are the regulatory and ADA compliance aspects to consider during the elevator installation in a new commercial building?

ADA rules call for a cab at least 51 inches deep by 68 inches wide, with a door opening of at least 36 inches. There also needs to be an emergency communication system usable by everyone, including people with disabilities. On top of that, local codes often require fire service operation, backup power, and yearly safety inspections.